A catamaran unlike a monohull has the possibility of overturning and not coming back rightside up. A monohull can turn over too, but it will always right itself as long as the keel is still attached. A catamaran has two stable positions, right side up and upside down. Because it is possible for the boat to turn in the inverted position with people inside the hull, European boat manufacturers have required the inclusion of escape hatches which can be used to exit an upside down boat. To insure the hatch is as high above the water as possible when the boat is inverted, the hatch is placed at the waterline when the boat is in the rightside up position. All this is well and good, but for most cruising catamarans it is very unlikely the boat will turn over.

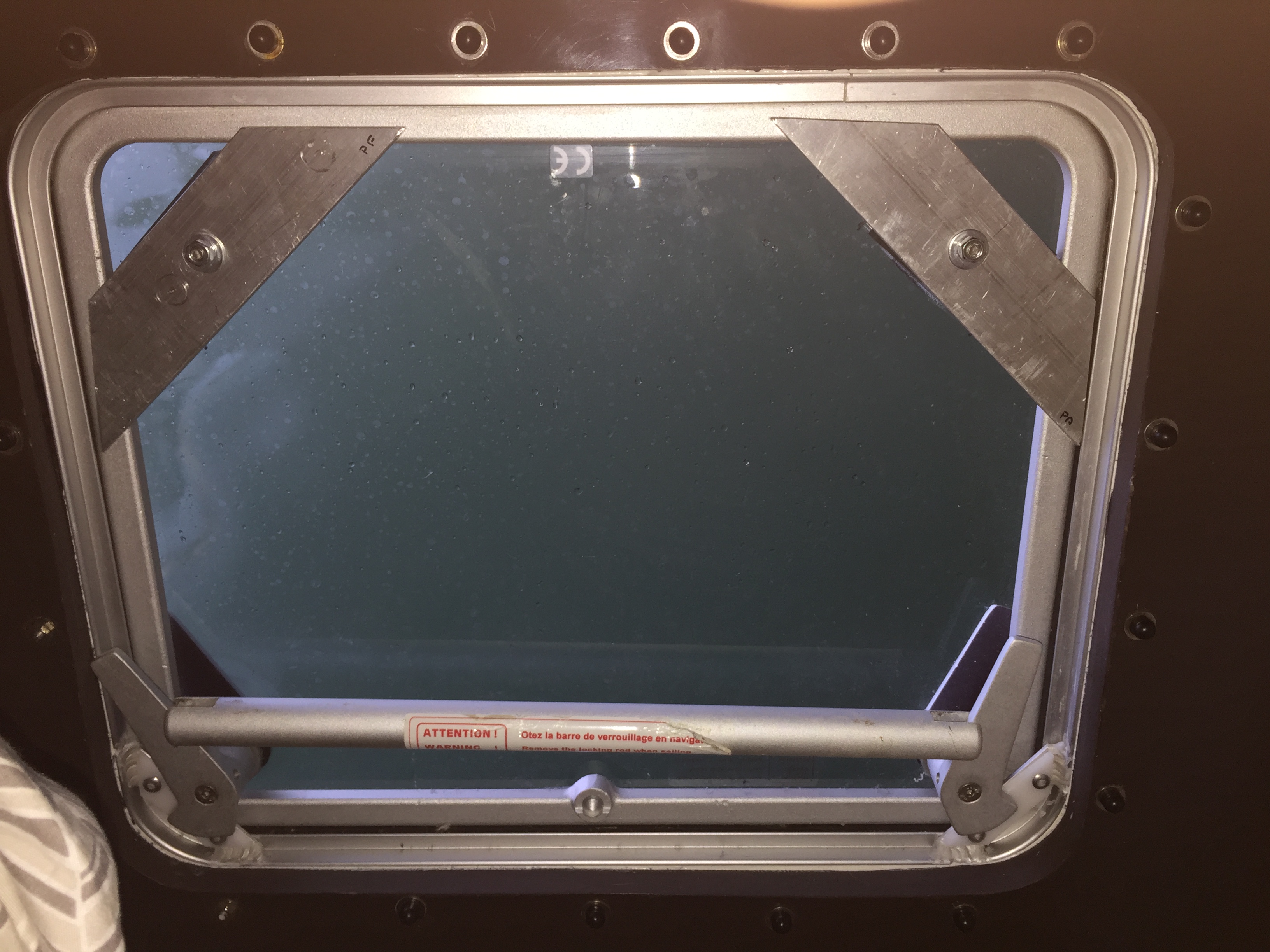

The hatch used on the Fountaine Pajot boats is manufactured by Goiot (another French company). It is specifically designed for use as an escape hatch and is rated to be used at the waterline. When we purchased Gemeaux, the marine survey highlighted that escape hatches leaked. It was also noted in the survey that these hatches often leak. I assumed the leak was between the seal and the lens of the ha tch. While it is likely that many hatches leak there, I was soon to find out there is a much more serious leak potential.

tch. While it is likely that many hatches leak there, I was soon to find out there is a much more serious leak potential.

After about 8 months of owning Gemeaux, we were in the Chesapeake Bay and the port hatch was leaking more than usual. Trying to pin down the leaks was difficult until I pushed slightly on the lens of the hatch and it moved outward. It was then I realized the hatch was not leaking at the seal but was leaking between the lens and frame of the hatch. This would require the hatch to be replaced.

After some work tracking down a US supplier for the hatch and having sticker shock of over $2000 for the hatch, I ordered the hatch and had the boat hauled out of the water to replace it (another $500 to get it out of the water). I carefully inspected the starboard hatch but it seemed fine, no movement between the frame and the lens on that side. Now, I felt prepared to brave the Atlantic on the way to Antigua, no more leaking hatches… or so I thought.

During our crossing all went well until about 500 miles from Antigua when at 8PM, Shiera noticed water on the floor in the starboard bathroom. It was then she saw water spraying across the companionway when Gemeaux hit a wave. The problem was the lens had become detached from the upper part of the frame and now was threatening to exit the boat altogether. If the lens did fall out, Gemeaux would be lost. It wouldn’t sink but it was very unlikely that we could do anything to fix a 3ft square hole at the waterline.

First order of business was to try to get the lens back into the frame. We had a 2-inch glass suction puller for lifting floor panels but couldn’t pull hard enough to get the lens back into the frame. The only viable option was to go in the dingy under the hull and try to knock the panel back in. How scary was that—to be in 6 ft seas at night under the boat? Each wave would drive the dinghy into the bottom of the boat. I was able to time the waves to get a fist on the lens and pound it back in place. Now we needed a more secure fix to finish our sail to Antigua.

In a scene right from Apollo 13, we dumped every adhesive we had on the table. After carefully discussing each choice, we decided on a ribbon of underwater 5-minute epoxy between the frame and the lens. Then we would put 5200 adhesive around the joint. Five minutes is not very long, so we carefully rehearsed our plan and then each of the crew prepared a strip of epoxy for a side of the lens while I went back underneath the boat in the dinghy. We pushed the lens back out, lined the epoxy in the joint and then pressed the lens back into the frame. We could see the epoxy had good coverage in the joint, but just didn’t know if was adhered well. Next, we lathered 5200 adhesive onto the joint between the frame and the lens. We decided to hove-to for the night to give the adhesives time to cure.

As I tried to sleep, I keep worrying that the lens would still pop out of the frame. At 4 AM I came up with an idea to adhere two plastic blocks to the lens with flathead screws drilled through. Then a board was fitted completely across the frame and the screws secured to the board. This effectively leveraged the lens into the frame. We tried several different glues (contact adhesive, silicone, superglue), finally settling on superglue to glue the plastic blocks to the lens. The problem is that acrylic doesn’t take very well to any adhesive, but in our testing, superglue seemed to work the best.

The completed fix held until we reached Antigua where I ordered another lens and had the boat hauled out again. We completed the repair on Thanksgiving Day and celebrated with a BBQed turkey dinner while Gemeaux sat on the hard.

Now I realized the severe safety problem of the hatch. It wasn’t just the hatch that could leak, the entire lens could fall out the boat! The irony is the frame of the hatch is secured with 20 bolts that go through the hull, but the lens is only secured with a thin bead of silicone to frame and silicone does not adhere well to acrylic. I sent a strongly-worded email to both the US Fountaine Pajot dealer and Goiot, the maker of the hatch. I explained that a boat could be lost because of this problem. Unfortunately I didn’t get much of a reply. Goiot said they had no knowledge of failures like this and offered to send new glue to adhere the hatch to the frame. That was not very comforting.

I decided I could rig a permanent fix for the problem along the lines of a temporary fix. I researched how to attach acrylic to acrylic and found that solvent glue would weld two pieces together. It works by effectively melting the surface of each piece allowing the pieces to join as one. Rather than fit a board across, I used 1/8” aluminum stock in the upper corners across the frame. This still allows the hatch to be fully functional but is impossible for the lens to come out of the frame. The specs on the solvent glue are nearly 10,000 lbs for each 2×2” block. I could lift the entire boat up with that!

In the meantime, our hatch failure was reported on the Cruiser Forum by a boat that had been nearby when it failed. On the forum, I documented the failure, the response from Goiot and my fix. A number of people requested drawings for the fix.

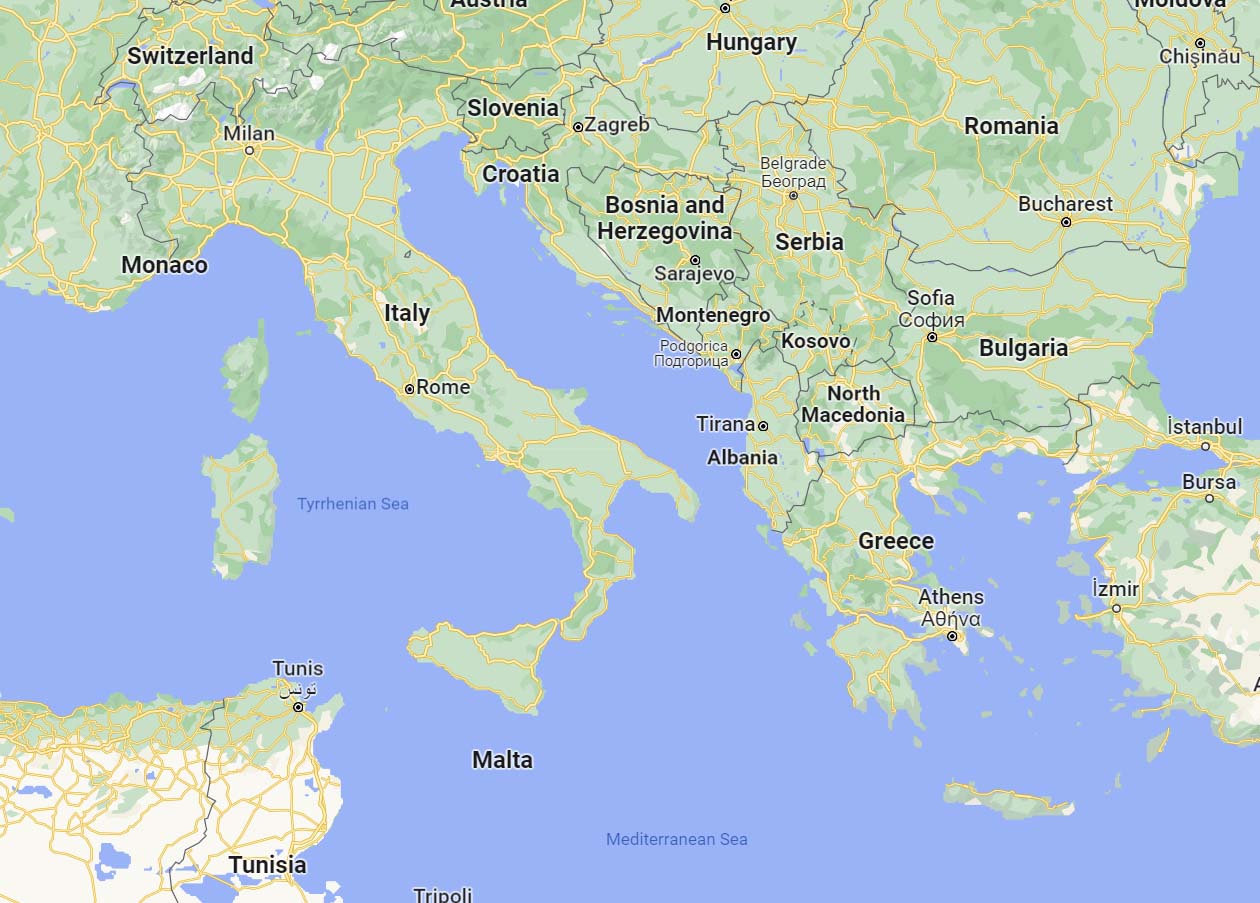

All was quiet for the next 6 months until on the Fountaine Pajot Owners Facebook page a Helia like Gemeaux was reported lost at sea off Africa. The speculation was the boat had hit something in the water and had a large hole punctured in the hull. Looking at photos of the boat, it seemed odd there was no damage to the bow of the boat. Pretty hard to hit something sideways. I tracked down the skipper in Norway and determined the problem was his starboard escape hatch had left the boat at 2 AM in rough seas. He tried many things to stop the inflow of water but ended up being rescued by the Moroccan coast guard and abandoning the boat. This was the exact problem we had, but his lens had completely left the boat.

I posted the information that this was another hatch failure like Gemeaux’s but the hatch had actually left the boat. I included the drawings for the fix and strongly suggested that all owners with the hatch immediately apply a fix to their hatch. Two weeks later another owner off the coast of Brazil had their hatch partially leave the frame. This was now three boats in less than a year that I knew about. I notified the Coast Guard of a potential safety problem (never heard back). Within a month, Fountaine Pajot was notifying owners of the problem and a fix Goiot had developed. I’m not a fan of the fix as it relies on an adhesive bond to acrylic rather than solvent glue to hold the lens in place. I would not bet my life on any adhesive bond with acrylic.

Over the past 6 months, I have been contacted by dozens of owners who want the fix. I have sent a dozen or so people a kit to install and the instructions to many others. Hopefully boats are better prepared now to secure a hatch that is very unlikely to be used for its intended purpose, but could be a disaster like the poor boat off of Africa, or what nearly occurred to Gemeaux in the Atlantic.

Thanks goodness you and Shiera are safe — that was scary story!! I have enough to worry about in this country and now I have to worry about you two sailing around! Be safe and sound❤️

Nice design, Nice write-up!

So sad this boat builder seems to be oblivious to the risks involved with their choice of escape hatches! Good engineers choose “fail-safe” solutions….

we have a Bali 2016, and we did sink quite in Paxos, due to the fall of the window of the security. hatch!!! 4 days ago. We are safe but it was minus 1 to arrive on the harbor on. 1 motor! 2/3 of the boat was already under the water….

Hello. I am on a lagoon 40. I tried the fix you suggested. With the adhesive shown. ( I was given tube from sv Otium last spring). However the adhesive does not bond with the hatch. It bonds well with the acrylic wedges. Thoughts? Could the adhesive be old?

Thanks in advance.

Joe

Joev71@hotmail

SV Inca Cross

Not sure what year Lagoon you have but on most they use tempered glass which you can’t adhere anything to. Lagoon came up with a funky fix with little clips screwed to the hull, but I heard the clips fall off pretty quick. If it was me I would explore adding a ring that encircled the entire hatch and was attached to the hull much more securely.

Just happened again off the coast of NC.